Quality & Steiff Schulte: a good fit.

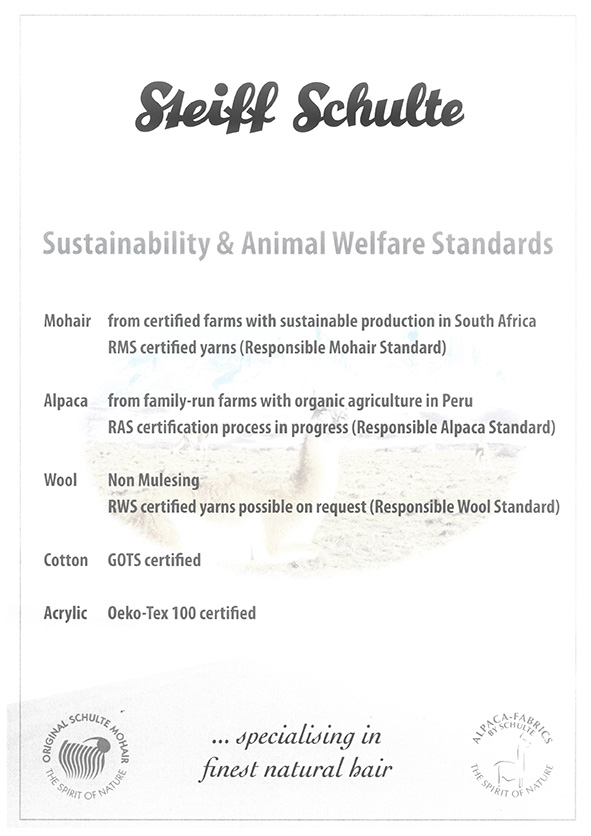

What does quality mean to us? It means everything. Where does it become tangible? First and foremost, of course, in the products that are, after all, known for this around the world: fabrics of tangibly, palpably, and visibly high quality, with charisma and long service lives.

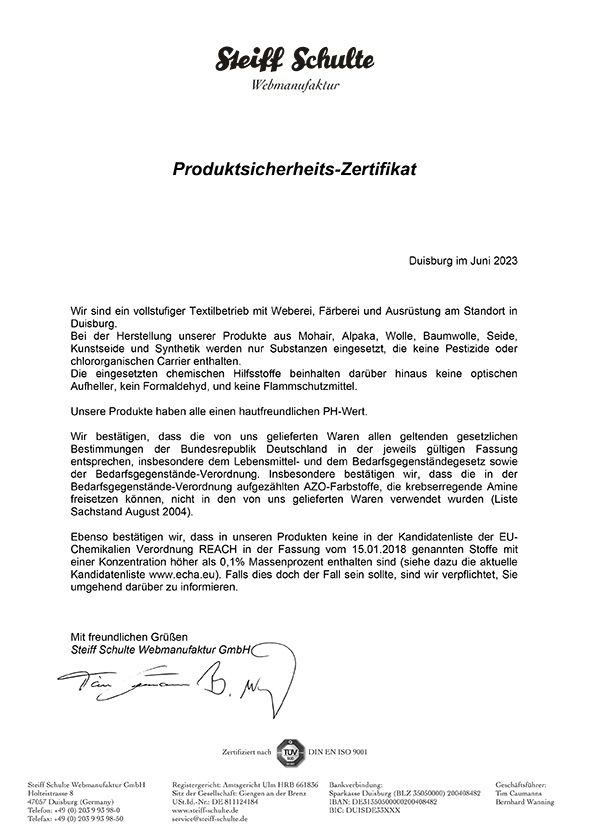

All of this is based on production quality. We use reliable machinery and our equally comprehensive and tried-and-tested QMS (quality management system) with material and manufacturing controls alike on all steps of production, from the first thread to delivery.

Speaking of delivery: Our service, including documentation and information, constant availability of a contact for our customers, and after-sales service that does not stop at handover of the goods, contributes to rounding off the quality experience offered by Steiff Schulte. Quality is an all-encompassing factor for us and producing excellent products before carelessly “throwing them on the market” is not what quality means to us.